Laser — 600–1000 nm lasers are

most basic for non-experimental applications. They are reasonable, yet since

they can be centered and effectively consumed by the eye, the most extreme

force is constrained by the need to make them eye-safe. Eye-wellbeing is

regularly a necessity for generally applications. A typical option, 1550 nm

lasers, are eye-protected at much higher force levels since this wavelength is

not concentrated by the eye, yet the indicator engineering is less progressive

thus these wavelengths are by and large utilized at longer ranges and lower

correctnesses. They are likewise utilized for military applications as 1550 nm

is not unmistakable in night vision goggles, not at all like the shorter 1000

nm infrared laser. Airborne topographic mapping lidars for the most part

utilize 1064 nm diode pumped YAG lasers, while bathymetric frameworks by and

large utilize 532 nm recurrence multiplied diode pumped YAG lasers on the

grounds that 532 nm enters water with considerably less constriction than does

1064 nm. Laser settings incorporate the laser reiteration rate (which controls

the information gathering pace). Beat length is by and large a trait of the

laser depression length, the quantity of passes needed through the addition

material (YAG, YLF, and so forth.), and Q-switch speed. Better target

determination is attained to with shorter heartbeats, gave the lidar

beneficiary identifiers and gadgets have sufficient data transfer capacity.

Scanner and optics —

How quick pictures can be produced is additionally influenced by the rate at

which they are filtered. There are a few alternatives to output the azimuth and

height, including double swaying plane mirrors, a blend with a polygon reflect,

a double pivot scanner (see Laser filtering). Optic decisions influence the

rakish determination and range that can be discovered. A gap mirror or a pillar

splitter are choices to gather a return signal.

Photodetector and recipient

gadgets — Two fundamental photodetector advances are utilized as a part of

lidars: robust state photodetectors, for example, silicon torrential slide

photodiodes, or photomultipliers. The affectability of the recipient is an

alternate parameter that must be adjusted in a lidar outline.

Position and route frameworks —

Lidar sensors that are mounted on portable stages, for example, planes or

satellites oblige instrumentation to focus irrefutably the position and

introduction of the sensor. Such gadgets by and large incorporate a Global Positioning

System collector and an Inertial Measurement Unit (IMU).

3d imaging can be attained to

utilizing both examining and non-checking frameworks. "3d gated review

laser radar" is a non-checking laser going framework that applies a beat

laser and a quick gated cam.

Imaging lidar can likewise be

performed utilizing clusters of rapid finders and tweak delicate indicator

shows ordinarily based on single chips utilizing CMOS and half breed CMOS/CCD

creation systems. In these gadgets every pixel performs some nearby preparing,

for example, demodulation or gating at rapid, downconverting the signs to

feature rate with the goal that the show may be perused like a cam. Utilizing

this method numerous a great many pixels/ channels may be gained at the same

time. High determination 3d lidar cams use homodyne identification with an electronic

CCD or CMOS screen.

An intelligible Imaging lidar

utilizes Synthetic exhibit heterodyne identification to empower a gazing single

component recipient to go about just as it were an imaging cluster.

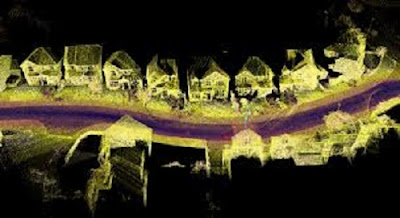

In 2014 Lincoln Laboratory

proclaimed another imaging chip with more than 16,384 pixels, every ready to

picture a solitary photon, empowering them to catch a wide zone in a solitary

picture. A prior era of the innovation with one-quarter the same number of

pixels was dispatched by the U.s. military after the January 2010 Haiti seismic

tremor; a solitary pass by a business plane at 3.000 meters (10.000 ft.) over

Port-au-Prince had the capacity catch immediate depictions of 600-meter squares

of the city at 30 centimeters (12 in)[clarification needed], showing the exact

stature of rubble strewn in city roads. The new framework is an alternate 10x

quicker. The chip utilizes indium gallium arsenide (IGA), which works in the

infrared range at a moderately long wavelength that takes into consideration

higher force and more ranges. In numerous applications, for example, heading

toward oneself autos, the new framework will lower costs by not obliging a

mechanical part to point the chip. IGA

utilizes less dangerous wavelengths than customary silicon finders, which work

at visual wavelengths.